Ethernet Communication

What is the Ethernet?

Ethernet in the FA environment

There are two types of networks in an FA environment: a "information network" and a "control network."

Information Network

In an information network, computers are routinely utilized to communicate and acquire data.

A large amount of data is frequently sent over a long period of time, ranging from few minutes to many hours. An information network is used to convey production instructions to a production site and to receive production status updates from a production site.

Network example: Ethernet

Control Network

In control networks, programmable controllers are often used to send and collect information in bit and word forms.

Because synchronization of information and assembly line processes is frequently required, only a limited amount of data is reliably sent in millisecond intervals.

The control network, among other things, is used to convey sensor and actuator on/off statuses, workpiece position information, and motor rotation speed.

Examples of networks: CC-Link IE Controller Network, CC-Link IE Field Network, and CC-Link Network are all examples of CC-Link networks.

Ethernet in the FA environment

Ethernet is one of the information network protocols.

As the demand for information connections between factories and offices has expanded in recent years, Ethernet is gaining favor as a network standard for transferring instructions to the factory floor and receiving production status reports.

Ethernet Basics

This section describes the TCP/IP protocols that are typically utilized by Ethernet.

For devices to communicate, both the communication source and destination devices must be specified. They are the same as the sender's and receiver's addresses on an envelope.

IP address

TCP/IP communication is based on IP communication. In IP communication, each communication device is identified by its IP address (Internet Protocol address). These addresses are often expressed in decimal and are divided into four 8-bit sections by dots (e.g., "192.168.1.1").

Oto 65535 to Oto 65535 are the port numbers. (From 0 to FFFF) Each application program has its own set of 'Well Known Port Numbers,' which range from 0 to 1023 (0 to 3FF). (For example, the email recipient port is 25, the homepage reference port is 80, and the file transfer port numbers are 20 and 21.)

The port numbers 1025 to 65534 (401 to FFFE) are used for communication between unlinked programmable controllers.

- Port numbers are expressed in decimal in this section. In parentheses are hexadecimal values.

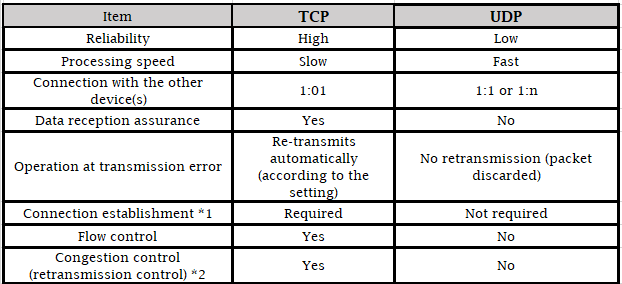

Communication Methods

Application:

- Protocol for Industrial Ethernet Communication:

- Synopsis

Like other technologies, industrial communications has evolved considerably. Serial networks formerly dominated the industry, and they deployed technology that fit market demands at the time. Higher throughput and rates are now necessary to accommodate new, more complicated slave devices, as well as end-node equipment and new applications. As a result, industrial communications equipment has shifted to faster, more deterministic Ethernet-based technologies and protocols, however no one protocol has emerged as the industry's dominant communication standard. In today's market, slave communications are provided via a range of communication protocols, each with its own set of capabilities and benefits.

- Slave Equipment for the Industrial Sector

We'll examine prior serial-based protocols, as well as industrial Ethernet protocols, and see how they integrate into the industrial automation context, as depicted in Figure 1, to offer real-time, determinism, and low latency for industrial communications.

Manufacturers encounter a number of challenges when it comes to industrial slave equipment. Industrial slave equipment includes PLCs, industrial drives, fieldbus sensors, human/machine interface systems, grid infrastructure communications, industrial gateways, and other systems. The majority of the hardware is intended to execute protocols.

- Components of Industrial Automation

Communication is essential for all industrial automation components for efficient production systems. The four basic components of industrial automation are PLC controllers, HMI panels, industrial drives, and sensors. Figure 2 displays the primary components of industrial automation and how they interact.

The PLC controller serves as the central processing unit (CPU) of an industrial automation system, controlling relays, movements, industrial input and output processes, distributed systems, and network connections.

HMI stands for graphical user interface for industrial control. It has a command input and feedback output interface for running industrial machinery. Through common communication links, an HMI is linked to numerous components of an industrial system.

Industrial drives are motor controllers that allow motors to run as efficiently as possible. They come in a variety of voltage and power levels and are used in a number of industrial applications. Industrial drives include AC and DC drives, as well as servo drives that use a motor feedback system to govern and adjust the behavior and performance of servo mechanisms.

Sensors provide direct measurement for industrial automation systems, which continually monitor industrial operating conditions, inspections, position measurements, and other functions. They are an essential component of industrial automation systems because they provide system control via trigger points and feedback.

- Industrial Communication Protocol

- PROFIBUS

- CAN

The Control Area Network (CAN) bus is a high-quality serial bus system. It originated as a vehicle bus for automobiles and later evolved into one of the fieldbuses used in industrial automation. It includes a physical and data connection layer that allows for serial communication at speeds of up to 1Mbps. CANopen and DeviceNet are higher-level protocols that are constructed on top of the CAN bus to enable devices on the same industrial network to interact with one another. On the same network, CANopen has 127 nodes while DeviceNet has 64 nodes.

- Modbus

Modbus is a straightforward, dependable, and open serial bus that may connect up to 247 nodes on a single connection. Modbus is a basic protocol that runs via RS-232 or RS-485 with physical connection speeds of up to 115K baud.

0 Comments