Soft Starter

What is the Soft Starter?

Everyone who deals with engines is well aware of the traditional starting methods such as “direct on line” and “star/delta” and what they have from some undesirable aspects on each of the electrical network - motors - and mechanical equipment.

There are also some applications that are not fully suitable for the previous methods. As for the “directly on-line” method, the value of the starting current is in the range of 4-8 times the rated current, which represents a burden on both the supply network and the motor, which is taken into account when designing and selecting network components such as feeders and necessary protections.

Also, the value of the starting torque is estimated at about one and a half times the rated value of the motor torque, which also constitutes a mechanical burden on all the mechanical parts of the motors and equipment. As for the star / delta starting method, the value of the starting current is from 2 to 3 times the rated current .. And the value of the starting torque is less than Rated torque of the motor.

In spite of that, it is known that at the moment when the motor winding method is changed from “star” to “delta”, this is accompanied by the occurrence of transient currents of very high maximum values ... From the above it becomes clear the need to use new means to start The movement of the motors performs the desired purpose while avoiding the side effects of the traditional methods ... Hence the idea of using semiconductors to make quiet starters arose.

working theory:

The two processes of disconnecting and connecting the motors are controlled by thyristors so that the source voltage is gradually shed over a specified period of time until it reaches its full value by the end of the operating period. Likewise, the motor stop period can be controlled by gradually reducing the source voltage from its full value to zero during a specified period of time. Thus, stopping and running can be done without sudden and sharp changes in any of the current or torque, which leads to avoiding many electrical and mechanical difficulties.

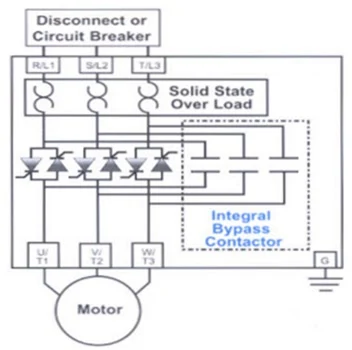

The following figure shows the installation of the Soft Starter

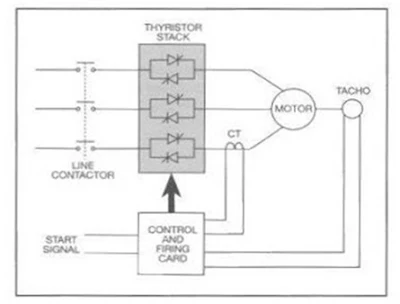

The following figure shows how it works, where the speed and current signals of the motor are entered into a control circuit, and based on the speed and current values, this circuit controls the firing angles of the thyristors, and thus the voltage value is changed.

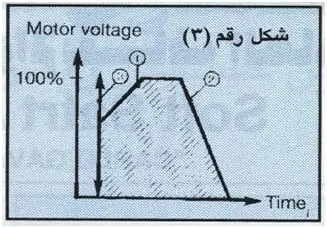

The following figure shows the curve of voltage change with time for quiet starters and stops, with the possibility of controlling the operating time, stopping time and starting torque to suit different applications.

And by using the soft start process, the voltage is adjusted so that the values of the motor currents when starting are just enough to give the motor a torque equal to the load torque at the start.. These values, of course, will not lead to rotation of the motor and the load, but they lead to starting without mechanical or electrical stresses.. Then the The starting device is to increase the voltage applied to the motor with time until the speed increases until it reaches its highest value, where the voltage has reached its rated value.

Advantages of using Soft Starter:

1- Reducing the starting current to a value that can be tolerated by the motor windings.

2- Maintaining the stability of the network voltage, because the high starting current leads to a reduction in the network voltage, which causes problems for the rest of the loads.

3- Provide electrical power during start-up periods - some soft-start devices can provide power during engine operation periods

4- Using a small cross-sectional area for cables connected from the network to the engine.

5- Using the "Star/Delta" key start method, we need two cables, each with three ends, from the engine to the key.. But using the soft start device, you only need a three-pin cable.

6- It rarely needs maintenance because it does not contain moving parts.

7- It helps to start the engine rotation without mechanical or electrical stresses to the engine or loads.

Applications :

From the above, we can realize the wide range of applications in which quiet start and stop starters are used, for example .... In the case of conveyor belts, which are widely used in transmission and packing lines - it is clear that the process of stopping and running should take place without any sudden movements, otherwise this will lead to The occurrence of product losses, and here the use of this type of starter becomes a necessity and not an option. It is also used efficiently in cranes and hoists in order to ensure a quiet movement during lifting and unloading loads. It is also used in plastic packaging machines, as well as with pumps and compressors, as this leads to avoiding sudden changes in the pressure of gases and liquids. Inside the pipes, which eliminates the phenomenon of hammering inside the pipes.

0 Comments